For roughing of steel PH / PX Chipbreaker - Kyocera

For roughing of steel PH / PX Chipbreaker - Kyocera

For roughing of steel PH / PX Chipbreaker - Kyocera

You also want an ePaper? Increase the reach of your titles

YUMPU automatically turns print PDFs into web optimized ePapers that Google loves.

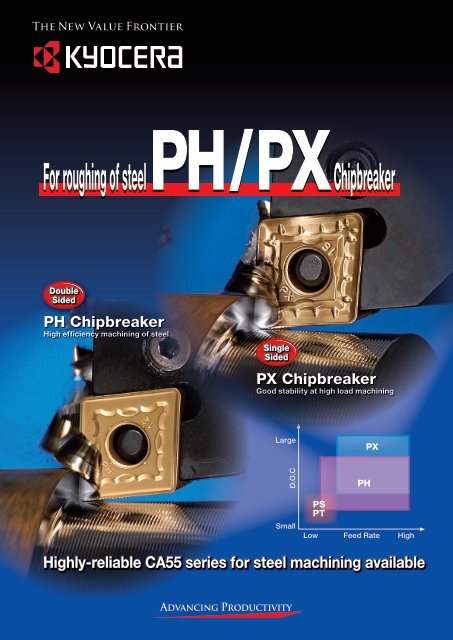

<strong>For</strong> <strong>roughing</strong> <strong>of</strong> <strong>steel</strong> <strong>PH</strong> / <strong>PX</strong> <strong>Chipbreaker</strong><br />

Double<br />

Sided<br />

<strong>PH</strong> <strong>Chipbreaker</strong><br />

High efficiency machining <strong>of</strong> <strong>steel</strong><br />

Single<br />

Sided<br />

<strong>PX</strong> <strong>Chipbreaker</strong><br />

Good stability at high load machining<br />

Large<br />

D.O.C<br />

Small<br />

PS<br />

PT<br />

<strong>PH</strong><br />

<strong>PX</strong><br />

Low Feed Rate High<br />

Highly-reliable CA55 series for <strong>steel</strong> machining available

Double Sided <strong>Chipbreaker</strong> for <strong>roughing</strong> <strong>of</strong> <strong>steel</strong><br />

<strong>PH</strong><strong>Chipbreaker</strong><br />

■ Advantages<br />

∙Suitable for heavy interrupted cutting and for workpiece with scale due<br />

to strong cutting edge<br />

∙Smooth chip control by wide and shallow chipbreaker design<br />

∙Prevents crater wear by positive land on insert corner<br />

Positive land on insert corner<br />

controls crater wear<br />

Wide land design<br />

High strength<br />

■ Stock Items<br />

Shape Description<br />

CNMG 120408<strong>PH</strong><br />

120412<strong>PH</strong><br />

120416<strong>PH</strong><br />

Dimension(mm)<br />

I.C.<br />

Thickness<br />

Hole<br />

12.70 4.76 5.16<br />

CNMG 160608<strong>PH</strong><br />

160612<strong>PH</strong> 15.875<br />

160616<strong>PH</strong><br />

6.35 6.35<br />

CNMG 190608<strong>PH</strong><br />

190612<strong>PH</strong><br />

190616<strong>PH</strong><br />

190624<strong>PH</strong><br />

DNMG 150408<strong>PH</strong><br />

150412<strong>PH</strong><br />

150416<strong>PH</strong><br />

DNMG 150608<strong>PH</strong><br />

150612<strong>PH</strong><br />

150616<strong>PH</strong><br />

SNMG 120408<strong>PH</strong><br />

120412<strong>PH</strong><br />

120416<strong>PH</strong><br />

19.05 6.35 7.94<br />

12.70 4.76 5.16<br />

12.70 6.35 5.16<br />

12.70 4.76 5.16<br />

SNMG 150612<strong>PH</strong><br />

15.875 6.35 6.35<br />

150616<strong>PH</strong><br />

SNMG 190612<strong>PH</strong><br />

190616<strong>PH</strong><br />

190624<strong>PH</strong><br />

TNMG 160408<strong>PH</strong><br />

160412<strong>PH</strong><br />

TNMG 220408<strong>PH</strong><br />

220412<strong>PH</strong><br />

220416<strong>PH</strong><br />

19.05 6.35 7.94<br />

9.525 4.76 3.81<br />

12.70 4.76 5.16<br />

Corner-R (rε)<br />

0.8<br />

1.2<br />

1.6<br />

0.8<br />

1.2<br />

1.6<br />

0.8<br />

1.2<br />

1.6<br />

2.4<br />

0.8<br />

1.2<br />

1.6<br />

0.8<br />

1.2<br />

1.6<br />

0.8<br />

1.2<br />

1.6<br />

1.2<br />

1.6<br />

1.2<br />

1.6<br />

2.4<br />

0.8<br />

1.2<br />

0.8<br />

1.2<br />

1.6<br />

Stock Grades<br />

CVD Coated Carbide<br />

CA5505<br />

CA5515<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

CA5525<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

CA5535<br />

●:Standard Stock :Check Availability<br />

Large<br />

Cutting Load (feed x depth <strong>of</strong> cut)<br />

Small<br />

Application<br />

Wide land design / Shallow chipbreaker<br />

Prevents chip clogging at high<br />

feed cutting<br />

Smooth chip breaking with wide and<br />

shallow chipbreaker<br />

■ Applicable <strong>Chipbreaker</strong> Range<br />

D.O.C<br />

(mm)<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

■ How to use <strong>PH</strong> (double sided) and <strong>PX</strong> (single sided)<br />

Continuous<br />

<strong>PX</strong><br />

<strong>PH</strong>(19 Type)<br />

<strong>PH</strong>(16 Type)<br />

<strong>PH</strong><br />

<strong>PH</strong>(12 Type)<br />

<strong>PX</strong><br />

∙<strong>For</strong> large depth <strong>of</strong> cut<br />

∙<strong>For</strong> reducing cutting force<br />

Light interruption Interruption<br />

(Steel)<br />

0.2 0.4 0.6 0.8 1.0<br />

Feed Rate (mm/rev)<br />

<strong>PH</strong><br />

∙<strong>For</strong> interrupted cutting /<br />

workpiece with scale<br />

∙<strong>For</strong> high feed rate

Single sided <strong>Chipbreaker</strong> for <strong>roughing</strong> <strong>of</strong> <strong>steel</strong><br />

<strong>PX</strong>Chipbreake<br />

■ Advantages<br />

∙Low cutting force by curved cutting edge design<br />

∙Prevents crater wear by positive land on insert corner<br />

∙Prevents adhesion by 2-steps dots and reduces load on dots<br />

■ Stock Items<br />

2-step dots<br />

Chip breaking while<br />

preventing adhesion<br />

0.37<br />

5°<br />

22°<br />

Shape Description<br />

CNMM 120408<strong>PX</strong><br />

120412<strong>PX</strong><br />

120416<strong>PX</strong><br />

CNMM 160608<strong>PX</strong><br />

160612<strong>PX</strong><br />

160616<strong>PX</strong><br />

CNMM 190608<strong>PX</strong><br />

190612<strong>PX</strong><br />

190616<strong>PX</strong><br />

190624<strong>PX</strong><br />

DNMM 150408<strong>PX</strong><br />

150412<strong>PX</strong><br />

150416<strong>PX</strong><br />

DNMM 150608<strong>PX</strong><br />

150612<strong>PX</strong><br />

150616<strong>PX</strong><br />

SNMM 120408<strong>PX</strong><br />

120412<strong>PX</strong><br />

120416<strong>PX</strong><br />

SNMM 150612<strong>PX</strong><br />

150616<strong>PX</strong><br />

SNMM 190612<strong>PX</strong><br />

190616<strong>PX</strong><br />

190624<strong>PX</strong><br />

TNMM 160408<strong>PX</strong><br />

160412<strong>PX</strong><br />

TNMM 220408<strong>PX</strong><br />

220412<strong>PX</strong><br />

220416<strong>PX</strong><br />

Positive land on insert corner<br />

Cutting force reduction at the point <strong>of</strong> first<br />

contact and controls crater wear<br />

Dimension(mm)<br />

I.C.<br />

Thickness<br />

Hole<br />

12.70 4.76 5.16<br />

15.875 6.35 6.35<br />

19.05 6.35 7.94<br />

12.70 4.76 5.16<br />

12.70 6.35 5.16<br />

12.70 4.76 5.16<br />

15.875 6.35 6.35<br />

19.05 6.35 7.94<br />

9.525 4.76 3.81<br />

12.70 4.76 5.16<br />

Corner-R (rε)<br />

0.8<br />

1.2<br />

1.6<br />

0.8<br />

1.2<br />

1.6<br />

0.8<br />

1.2<br />

1.6<br />

2.4<br />

0.8<br />

1.2<br />

1.6<br />

0.8<br />

1.2<br />

1.6<br />

0.8<br />

1.2<br />

1.6<br />

1.2<br />

1.6<br />

1.2<br />

1.6<br />

2.4<br />

0.8<br />

1.2<br />

0.8<br />

1.2<br />

1.6<br />

Stock Grades<br />

CVD Coated Carbide<br />

CA5505<br />

CA5515<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

CA5525<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

CA5535<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●<br />

●:Standard Stock<br />

0.34<br />

0°<br />

22°<br />

Curved edge<br />

Cutting force reduction at<br />

large ap<br />

CNMM190616<strong>PX</strong><br />

Wide land and large rake angle<br />

Good balance <strong>of</strong> sharpness<br />

and cutting edge strength<br />

■ Applicable <strong>Chipbreaker</strong> Range<br />

D.O.C<br />

(mm)<br />

12<br />

10<br />

8<br />

6<br />

4<br />

2<br />

<strong>PX</strong>(19 Type)<br />

<strong>PX</strong>(16 Type)<br />

<strong>PX</strong>(12 Type)<br />

(Steel)<br />

0.2 0.4 0.6 0.8 1.0<br />

Feed Rate (mm/rev)<br />

CNMM<br />

Chip by 100-degree corner<br />

(CNMM type)<br />

SCM415<br />

CNMM190616<strong>PX</strong>, Vc=120m/min<br />

ap=5mm, f=0.5mm/rev, WET<br />

■Chip control <strong>of</strong> CNMM type<br />

(100-degree corner)<br />

Chip control has been improved by large<br />

dots on chipbreaker when using 100-degree<br />

corner <strong>of</strong> CNMM type.

<strong>Chipbreaker</strong> for <strong>roughing</strong> <strong>of</strong> <strong>steel</strong><br />

<strong>PH</strong>/<strong>PX</strong><strong>Chipbreaker</strong><br />

■Case Studies<br />

∙Bearing<br />

∙Vc=130m/min<br />

∙ap=5~6mm<br />

∙f=0.5mm/rev<br />

∙WET<br />

∙CNMG190616<strong>PH</strong><br />

(CA5525)<br />

<strong>PH</strong><br />

Competitor A<br />

SUJ3<br />

ø1000<br />

Facing(with scale)<br />

∙<strong>PH</strong> chipbreaker doubled the number <strong>of</strong> processed<br />

workpiece due to double sided design compared<br />

with the competitor A (single sided).<br />

∙Shaft<br />

∙Vc=120m/min<br />

∙ap=8mm<br />

∙f=0.35mm/rev<br />

∙WET<br />

∙CNMM190612<strong>PX</strong><br />

(CA5515)<br />

<strong>PX</strong><br />

Competitor C<br />

16~28pcs/insert<br />

8~14pcs/insert<br />

SNCM616<br />

800<br />

more than18pcs/edge<br />

10pcs/edge<br />

(Evaluation by the user)<br />

8<br />

ø150<br />

With scale<br />

∙<strong>For</strong> Comp. C, dots on chipbreaker were worn away<br />

after processing 10pcs/edge.<br />

∙<strong>PX</strong> chipbreaker showed little wear even after<br />

processing 18pcs/edge and still available for<br />

further processing.<br />

(Evaluation by the user)<br />

∙Connector<br />

∙Vc=80m/min<br />

∙ap=10mm(<strong>roughing</strong>)<br />

∙ap=3.8mm(finishing)<br />

∙f=0.7mm/rev<br />

∙DRY<br />

∙CNMG190616<strong>PH</strong><br />

(CA5525)<br />

<strong>PH</strong><br />

Competitor B<br />

SCM440class<br />

1pcs/edge<br />

330<br />

1.5pcs/edge<br />

∙<strong>PH</strong> chipbreaker extended the tool life by 1.5 times<br />

<strong>of</strong> the competitor's coated insert B.<br />

∙Shaft<br />

∙Vc=230m/min<br />

∙ap=4mm<br />

∙f=0.5mm/rev<br />

∙WET<br />

∙CNMM190612<strong>PX</strong><br />

(CA5515)<br />

<strong>PX</strong><br />

Competitor D<br />

S45C<br />

2pcs/edge<br />

1000<br />

4pcs/edge<br />

ø500<br />

ø570<br />

(Evaluation by the user)<br />

ø120 20<br />

With scale<br />

∙<strong>PX</strong> chipbreaker showed two times longer tool life<br />

compared with Comp. D.<br />

(Evaluation by the user)<br />

- KYOCERA, Contributing To Advancing Productivity -